Are you puzzled by the many types of lift mechanisms? Lifts move people and goods up and down in buildings every day. This blog will explore the various types of lift mechanisms, including hydraulic and traction lifts.

Get ready to learn about the fascinating world of elevators and lifts!

Key Takeaways

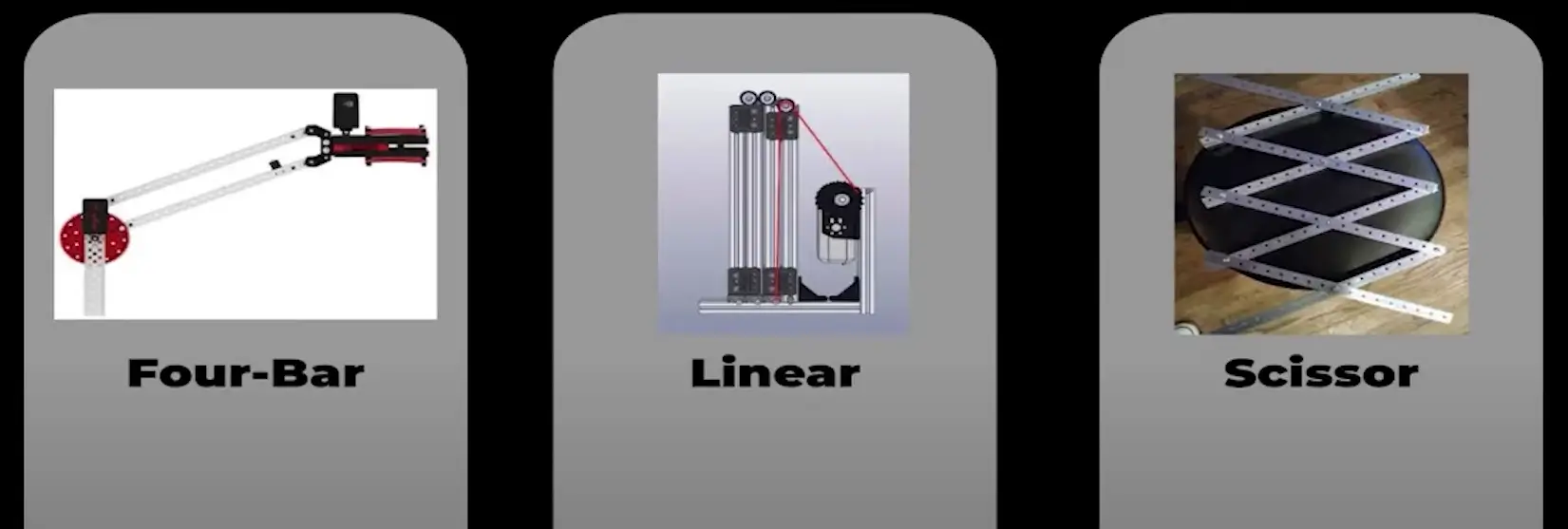

- Lift mechanisms come in three main types: hydraulic, traction, and scissor lifts. Each type has unique strengths for different uses.

- Hydraulic lifts use fluid power to move heavy loads smoothly. They’re great for outdoor use and can handle heavier weights than electric lifts.

- Traction lifts, powered by electric motors, use steel cables and counterweights. They’re energy-efficient and common in tall buildings.

- Regular maintenance is key for all lift types. This includes checking fluid levels, inspecting for damage, and lubricating moving parts.

- Common lift problems include hydraulic failures, power issues, and control malfunctions. Proper care and quick fixes can prevent most issues.

Overview of Lift Mechanisms for Overhead Doors

Lift mechanisms for overhead doors come in various types. Each type has its own strengths and uses.

Hydraulic Lifts

Hydraulic lifts use fluid power to move heavy stuff up and down. These handy devices work great for doors and gates. They pump special liquid into a cylinder, which pushes a piston up.

This action lifts the load smoothly and safely. Hydraulic lifts come in many types, like elevators, scissor lifts, and platforms. They’re tough enough for big jobs and outdoor use.

Safety is key with hydraulic lifts. They have cool features to keep everyone safe. Emergency brakes stop sudden drops. Buffer systems soften landings. Backup power keeps things running if the main power fails.

These lifts can handle heavier loads than electric ones. For big doors or gates, hydraulic lifts offer strong, steady support.

Traction (Mechanical) Lifts

Moving from hydraulic lifts, we now explore traction lifts. These mechanical marvels use steel wire ropes and a counterweight system. Electric motors power traction lifts, making them energy-efficient.

You’ll often find these lifts in tall buildings.

Traction elevators rely on steel cables, pulleys, and a counterweight to move. The main part is an electric motor that spins a sheave. This action winds and unwinds steel cables linked to the elevator car and counterweight.

This setup allows smooth up and down motion in high-rise structures.

Scissor Lifts

Scissor lifts are cool machines that help people work up high. They use a special system called hydraulics to push a platform up and down. These lifts come in handy for fixing doors, gates, and other tall stuff.

You can find different types of scissor lifts, like ones that run on electricity or diesel fuel. Some even work well on rough ground.

Scissor lifts make jobs safer and faster. Workers can reach high spots without climbing ladders. This cuts down on accidents at work sites. But scissor lifts can’t go as high as some other lifts.

They also don’t move around as easily in tight spaces. Still, many people like using scissor lifts for their door and gate projects.

Maintenance and Lubrication of Lift Mechanisms

Lift mechanisms need regular care to work well. Here’s a list of key maintenance and lubrication tasks for lift mechanisms:

- Check fluid levels daily. Low hydraulic fluid can cause lift failure.

- Inspect for damage often. Look for cracks, loose parts, or worn cables.

- Test safety features. Make sure all safety devices work properly.

- Clean the lift regularly. Remove dirt and debris to prevent wear.

- Lubricate moving parts. Use the right grease for each part.

- Monitor battery charge. Keep batteries full to avoid breakdowns.

- Schedule pro inspections. Experts can spot hidden issues.

- Replace worn parts promptly. Don’t wait for a part to fail.

- Keep records of all maintenance. This helps track the lift’s health.

- Train staff on proper use. Good habits reduce wear and tear.

- Check for odd noises or movements. These can signal problems.

- Adjust the tension on cables and chains. Proper tension is vital for safety.

- Clean and inspect the lift platform. A clean platform is safer to use.

- Test emergency stop buttons. These must work every time.

- Review and update safety procedures. Stay current with best practices.

Common Problems with Lift Mechanisms and How to Address Them

Lift mechanisms can face several operational issues. Here are common problems and ways to address them:

- Hydraulic system failures: These cause loss of lifting power or uneven platform movement. Fix by checking fluid levels, replacing worn seals, or repairing leaks in hydraulic lines.

- Power source problems: Sudden power loss or startup issues often stem from dead batteries or faulty charging systems. Resolve by replacing batteries or repairing the charging unit.

- Control system malfunctions: Unresponsive controls or erratic movements may occur due to damaged wiring or software glitches. Address by inspecting and repairing wiring or updating control software.

- Structural integrity concerns: Unusual noises, vibrations, or visible deformations signal overloading or metal fatigue. Solve by reducing load capacity or reinforcing structural components.

- Weak lifting platform: Scissor lifts may struggle to lift loads. Fix by checking hydraulic pressure, lubricating moving parts, or adjusting the lift mechanism.

- Safety feature failures: Malfunctioning safety systems put users at risk. Repair or replace faulty sensors, switches, or interlocks to ensure safe operation.

- Wear and tear: Regular use leads to component degradation. Address through routine maintenance, including lubrication, part replacement, and system adjustments.

- Environmental damage: Exposure to harsh conditions can cause corrosion or electrical issues. Protect lifts with proper storage and weather-resistant coatings.

Conclusion

Lift mechanisms come in many forms, each with unique strengths. From hydraulic lifts to scissor lifts, these devices make our lives easier. They help us move heavy loads and reach high places safely.

Regular care keeps lifts working well for years. Understanding lift types helps you pick the right one for your needs.

FAQs

1. What are the main types of lift mechanisms?

The main types of lift mechanisms include hydraulic lifts, pneumatic lifts, scissor lifts, and traction elevators. Each type uses different methods to raise and lower loads or people.

2. How do hydraulic lifts work?

Hydraulic lifts use fluid power to move heavy loads. They rely on Pascal’s law, using pressurized fluid to create force. This allows them to lift heavy items in warehouses, factories, and construction sites.

3. What are scissor lifts used for?

Scissor lifts are often used as aerial work platforms. They can extend vertically to reach high places. Construction workers and maintenance crews use them for tasks that need height access.

4. What safety features do modern lifts have?

Modern lifts prioritize safety. They have emergency brakes, overload sensors, and backup power systems. Many also use regenerative braking to save energy. These features make elevator rides safer for passengers.

5. How do pneumatic elevators differ from hydraulic ones?

Pneumatic elevators use air pressure instead of fluid to move. They’re often used in low-rise buildings. Unlike hydraulic lifts, they don’t need a machine room, making installation easier in some spaces.

6. What types of lifts are used in high-rise buildings?

High-rise buildings typically use traction elevators. These lifts move using cables and counterweights. They can travel faster and higher than hydraulic lifts, making them ideal for tall structures.